Blog

- Home

- Uncategorized

- Coating mode

Coating mode

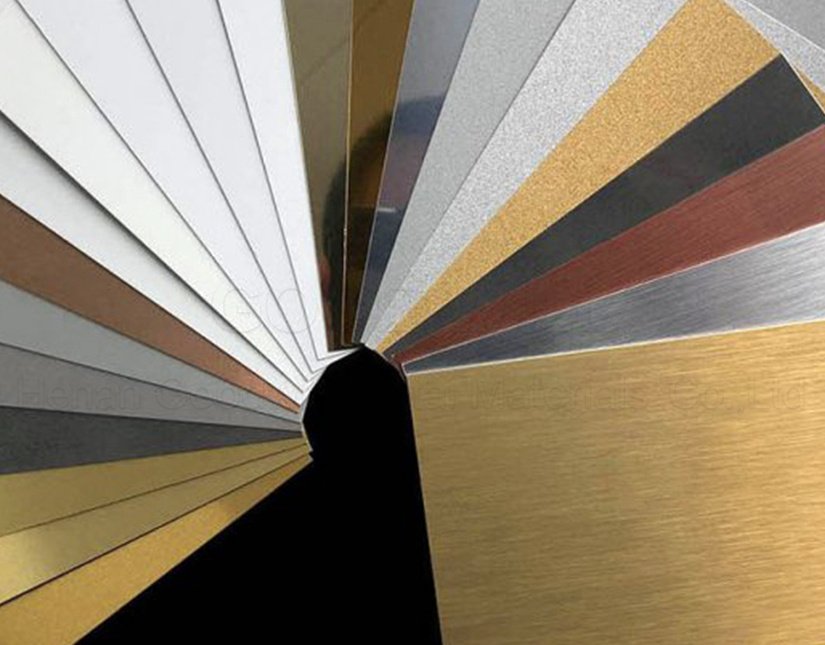

Color coated aluminum sheet is one of the important products of aluminum processing enterprises. Because of its light weight, bending resistance and corrosion resistance, it is widely used in various fields. Such as electronic equipment, architectural decoration, interior decoration and so on. The color aluminum sheet is durable. And the specially treated color coated aluminum plate can even reach 20 years and 30 years of long-term warranty.

Roll coating

Roller coating refers to the coating method of transferring the paint in the paint tray to the coating roller through the material roller. Then transferring the wet film of a certain thickness to the coating roller. Then transferring the wet film to the substrate surface. The thickness of the coating can be controlled within a certain range by adjusting the gap, pressure and speed of the roller. Using the roller coating method, the coating is very uniform and can be controlled within the error range of ±1 micron.

Advantages

With good temperature resistance and strong environmental protection, roller coating contains active chemical molecules to promote the formation of a protective layer on the surface of the material. Stable and easy to recycle active chemical molecules, in line with environmental requirements. High corrosion resistance, because its surface has a dense oxide film, with strong adhesion, soothing reactivity, acid and alkali resistance, corrosion resistance, decay resistance, UV radiation resistance and other characteristics.

Roller coating color uniform, long time, soft and gorgeous, to avoid the traditional spray single color difference phenomenon. No matter how large the ceiling area, its color is consistent, maintain constant new.

Painting coating

The process of spraying paint on the surface of an object by atomizing it with a spray gun. There are compressed air spray painting, high pressure airless spray painting, electrostatic spray painting. Spray painting operations use flammable paints that contain a lot of solvents. And solvent vapors that evaporate into the air under conditions requiring rapid drying are easy to form explosive mixtures.

Advantages

High production efficiency of spraying operation, suitable for industrial automation production, a wide range of applications, used in hardware, plastic, furniture, ships and other fields, is a widely used painting method; Spraying operation requires a dust-free workshop with high to one hundred levels of environmental requirements, spraying equipment has spray booth, curing furnace/drying furnace, equipment required for spraying operation has advanced to one hundred levels, spraying operation requirements have high to one hundred levels.

Defects

The main problem in the painting process is that the paint mist is highly dispersed and the solvent volatile. It is not only pollutes the environment, conducive to human health, but also wastes the paint and causes economic losses. Although the effect of painting molding is very uniform, the disadvantages are also obvious. That is the construction needs special equipment. The construction needs to protect other furniture doors and Windows more than the other two methods. It is estimated that 30% more than rolling coating, later if dirty need a wall to re-paint, later if dirty need a wall to re-paint.